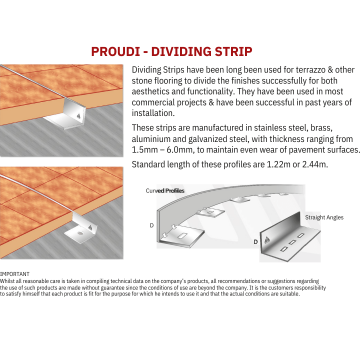

TILE MOVEMENT JOINTS: Movement joints are an essential part of any tile assembly. Different components of a tile assembly

(tile, mortar, substrate, etc.) have individual physical traits that affect their performance. These

components will expand and contract at different rates, according to each of their unique physical

properties, with changes in moisture, temperature and loading. This expansion/contraction of

attached components results in internal stress. Furthermore, structures that restrain the overall

expansion of the tile field (walls, columns, etc.) cause stress buildup within the system which will, in

turn, lead to cracking of grout and tile and loss of sheen.

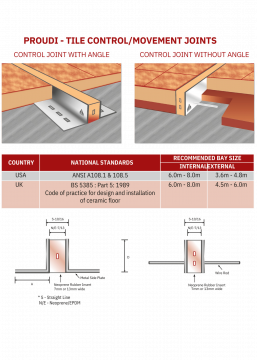

Control joints are used on floors to protect edges and to accommodate movements and local stress

including drying shrinkage, transient loading & thermal variation. These control joints, which are

normally about 20mm to 30mm high, must be sawed into the slab while the concrete is still green, at

a ‘weak point’ where the crack is likely to occur.

PRODUCT FEATURES

•Quick and easy installation- Can be installed while laying the wet underbed or adhesive.

•Requires only cutting to the length wherever necessary.

COMPONENTS:

•Stainless Steel-304 & 316, brass, aluminium & zinc side plates

•Brass or Stainless Steel side plates for external adhesive fixed application

•Quality Neoprene with air channels incorporated to allow maximum expansion and contraction

That means a good hard surface.

•Available colours – Black, Grey, Buff Grey and Beige

THICKNESS OF SIDE PLATES:

•Standard thickness is 1mm, 1.2mm, 1.5mm and the standard length is 2.4meters.

•Optional 3mm thick side plates available in brass and aluminium strips.

FINISHING:

•Top finishing has a 7mm or 13mm wide neoprene or EPDM as a standard rubber insert.

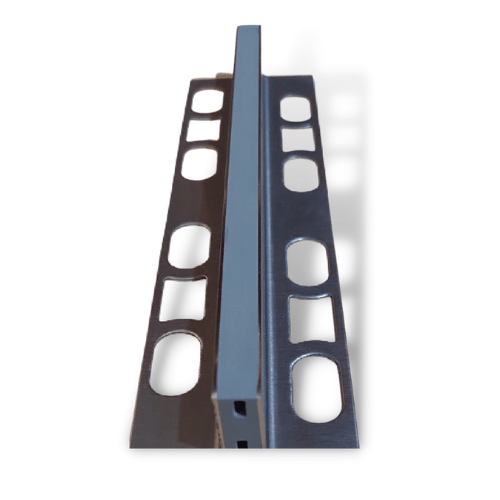

SIDE PLATE PUNCHING:

•Side plates are punches at regular intervals anchoring loops along the entire length of the strip.

•Also punched at regular intervals anchoring square holes for the adhesive.

•Tile movement joints are finished along the top view edges to provide a level finish with the

surface which can be easily maintained.

•Straightness of the Proudi movement joints maintained for storage and proper installation.

SPECIAL PROFILES

•Proudi can be supplied with only side plates excluding the angle.

There are no reviews yet.